- Product info

- Technical Parameters

Oil-free Screw Air Compressor Advantages:

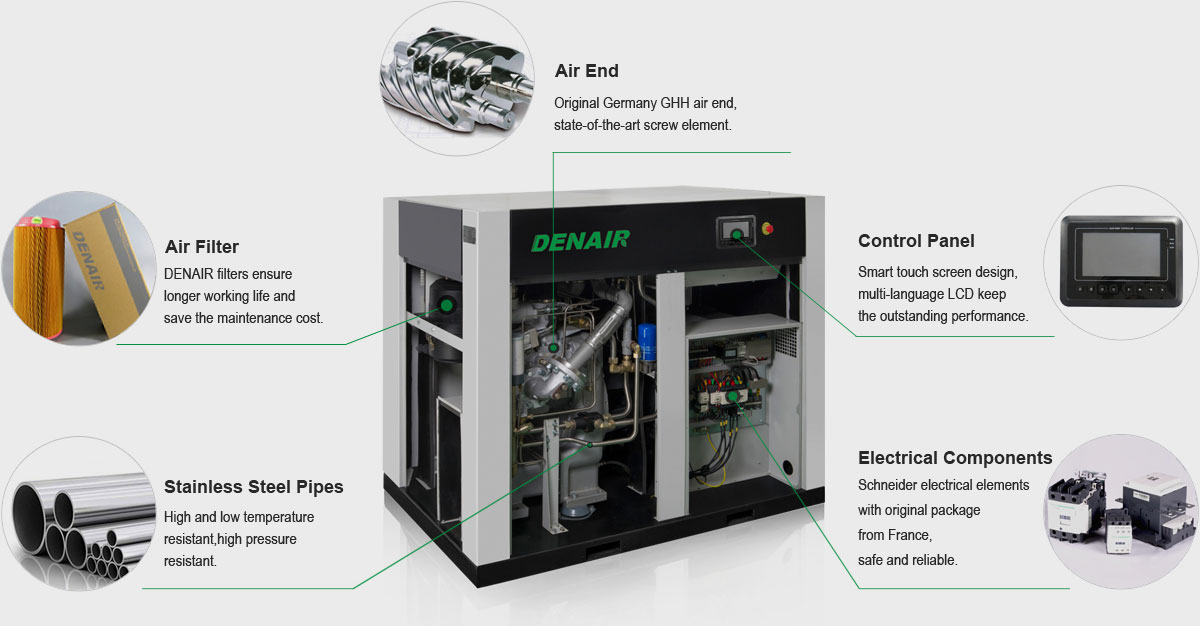

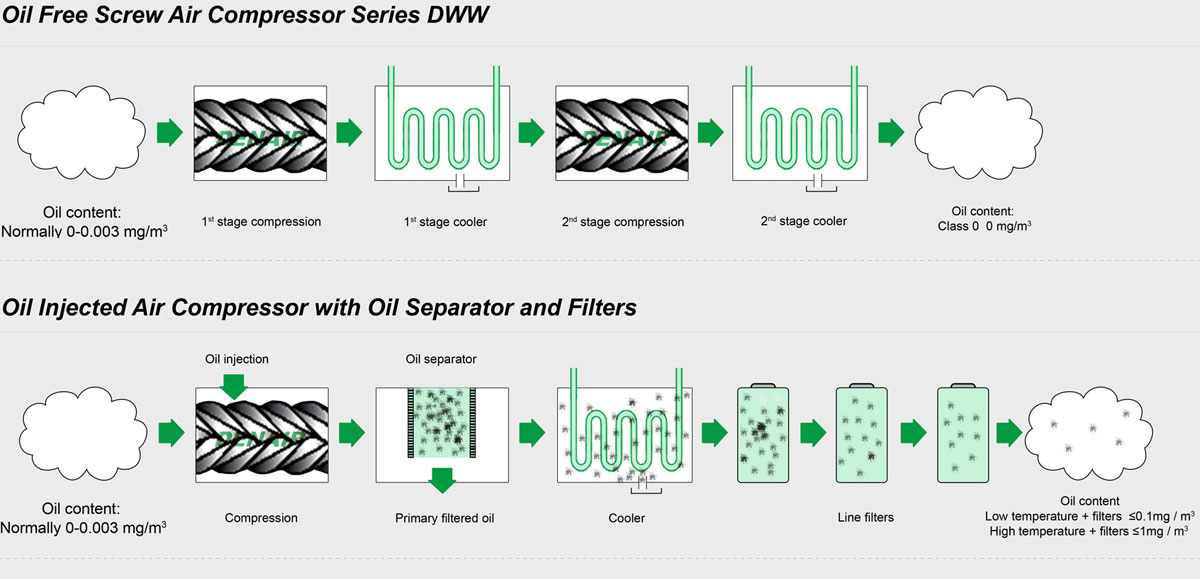

- Clean air 100% oil-free, class 0 oil free air according to ISO8573-1.

- Adopt GHH air end made in Germany.

- Technology patent used in oil free compressed air system.

- Significant energy saving, environmental-friendly and pollution-free.

- Low operation and maintenance cost.

- Powerful MAM microcomputer controller and touch screen.

- Designed especially for medical, pharmacy, instrument, coating, chemical industry and food processing, etc.

Working Pressure : 7.5-10.5 [ bar ] 109-152[ psig ]

Free Air Delivery : 7-150 [ cfm ] 0.21-4.25[ m3/min ]

Working Power : 2.2-37 [ kw ] 3-50[ hp ]

Oil-free Screw Air Compressor Technical Parameters:

| Model | Maximum working pressure | Capacity(FAD)* | Installed motor power | Cooling Method |

Noise Level** | Dimensions (mm) | Weight | Air Outlet Pipe Diameter |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 Hz | 60 Hz | ||||||||||||||

| bar(g) | psig | m³/min | cfm | m³/min | cfm | kW | hp | dB(A) | L | W | H | kG | |||

| DWW-45 | 7 | 102 | 7.07 | 250 | 7.16 | 253 | 45 | 60 | Air Cooling W-water Cooling |

80 | 2500 | 1600 | 2080 | 2630 | R1-1/2" |

| 8 | 116 | 7.03 | 248 | 6.48 | 229 | 45 | 60 | 80 | 2500 | 1600 | 2080 | 2630 | R1-1/2" | ||

| 10 | 145 | 5.51 | 194 | 5.37 | 189 | 45 | 60 | 80 | 2500 | 1600 | 2080 | 2630 | R1-1/2" | ||

| DWW-55 | 7 | 102 | 9.37 | 331 | 8.87 | 313 | 45 | 75 | 80 | 2500 | 1600 | 2080 | 2650 | R1-1/2" | |

| 8 | 116 | 9.34 | 330 | 8.25 | 291 | 55 | 75 | 80 | 2500 | 1600 | 2080 | 2650 | R1-1/2" | ||

| 10 | 145 | 8.11 | 286 | 7.10 | 251 | 55 | 75 | 80 | 2500 | 1600 | 2080 | 2650 | R1-1/2" | ||

| DWW-75 | 7 | 102 | 12.72 | 449 | 12.60 | 445 | 75 | 100 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | |

| 8 | 116 | 12.69 | 448 | 11.69 | 413 | 75 | 100 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | ||

| 10 | 145 | 11.58 | 409 | 10.43 | 368 | 75 | 100 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | ||

| DWW-75W | 7 | 102 | 12.72 | 449 | 12.60 | 445 | 75 | 100 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | |

| 8 | 116 | 12.69 | 448 | 11.69 | 413 | 75 | 100 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | ||

| 10 | 145 | 11.58 | 409 | 10.43 | 368 | 75 | 100 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | ||

| DWW-90 | 7 | 102 | 13.66 | 482 | 14.62 | 516 | 90 | 120 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | |

| 8 | 116 | 13.64 | 482 | 14.60 | 515 | 90 | 120 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | ||

| 10 | 145 | 12.64 | 446 | 12.86 | 454 | 90 | 120 | 82 | 2500 | 1600 | 2080 | 2850 | DN50 | ||

| DWW-90W | 7 | 102 | 13.66 | 482 | 14.62 | 516 | 90 | 120 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | |

| 8 | 116 | 13.64 | 482 | 14.60 | 515 | 90 | 120 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | ||

| 10 | 145 | 12.64 | 446 | 12.86 | 451 | 90 | 120 | 82 | 2300 | 1600 | 1790 | 2800 | DN50 | ||

| DWW-110 | 7 | 102 | 19.16 | 676 | 17.50 | 618 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | |

| 8 | 116 | 19.13 | 675 | 17.47 | 617 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | ||

| 10 | 145 | 16.72 | 590 | 15.41 | 544 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | ||

| DWW-110W | 7 | 102 | 19.16 | 676 | 17.50 | 618 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | |

| 8 | 116 | 19.13 | 675 | 17.47 | 617 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | ||

| 10 | 145 | 16.72 | 590 | 15.41 | 544 | 110 | 150 | 85 | 2800 | 1800 | 1860 | 3050 | DN65 | ||

| DWW-132 | 7 | 102 | 22.63 | 799 | 23.29 | 822 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | |

| 8 | 116 | 22.60 | 798 | 23.27 | 822 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| 10 | 145 | 20.28 | 716 | 20.46 | 723 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| DWW-132W | 7 | 102 | 22.63 | 799 | 23.29 | 822 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | |

| 8 | 116 | 22.60 | 798 | 23.27 | 822 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| 10 | 145 | 20.28 | 716 | 20.46 | 723 | 132 | 175 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| DWW-160 | 7 | 102 | 27.40 | 967 | 27.28 | 963 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | |

| 8 | 116 | 27.38 | 967 | 27.26 | 962 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| 10 | 145 | 23.98 | 847 | 26.38 | 931 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| DWW-160W | 7 | 102 | 27.40 | 967 | 27.28 | 963 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | |

| 8 | 116 | 27.38 | 967 | 27.26 | 962 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| 10 | 145 | 23.98 | 847 | 26.38 | 931 | 160 | 215 | 85 | 2800 | 1800 | 1860 | 3385 | DN65 | ||

| DWW-185 | 7 | 102 | 30.37 | 1072 | 31.20 | 1102 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | |

| 8 | 116 | 30.34 | 1071 | 31.04 | 1096 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | ||

| 10 | 145 | 27.34 | 965 | 29.16 | 1030 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | ||

| DWW-185W | 7 | 102 | 30.37 | 1072 | 31.20 | 1102 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | |

| 8 | 116 | 30.34 | 1071 | 31.04 | 1096 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | ||

| 10 | 145 | 27.34 | 965 | 29.16 | 1030 | 185 | 250 | 85 | 2800 | 1800 | 1860 | 3685 | DN65 | ||

| DWW-200W | 7 | 102 | 34.17 | 1206 | 34.82 | 1229 | 200 | 270 | 88 | 3100 | 2150 | 2200 | 4500 | DN100 | |

| 8 | 116 | 34.14 | 1205 | 34.78 | 1228 | 200 | 270 | 88 | 3100 | 2150 | 2200 | 4500 | DN100 | ||

| 10 | 145 | 30.55 | 1079 | 28.42 | 1004 | 200 | 270 | 88 | 3100 | 2150 | 2200 | 4500 | DN100 | ||

| DWW-220W | 7 | 102 | 36.71 | 1296 | 37.35 | 1319 | 220 | 300 | 88 | 3100 | 2150 | 2200 | 4750 | DN100 | |

| 8 | 116 | 36.66 | 1295 | 37.30 | 1317 | 220 | 300 | 88 | 3100 | 2150 | 2200 | 4750 | DN100 | ||

| 10 | 145 | 34.03 | 1202 | 31.30 | 1105 | 220 | 300 | 88 | 3100 | 2150 | 2200 | 4750 | DN100 | ||

| DWW-250W | 7 | 102 | 43.71 | 1543 | 44.27 | 1563 | 250 | 350 | 90 | 3100 | 2150 | 2200 | 4950 | DN100 | |

| 8 | 116 | 43.66 | 1542 | 44.24 | 1562 | 250 | 350 | 90 | 3100 | 2150 | 2200 | 4950 | DN100 | ||

| 10 | 145 | 39.16 | 1383 | 37.20 | 1314 | 250 | 350 | 90 | 3100 | 2150 | 2200 | 4950 | DN100 | ||

| DWW-280W | 7 | 102 | 47.65 | 1683 | 47.25 | 1668 | 280 | 375 | 92 | 3400 | 2400 | 2200 | 5100 | DN100 | |

| 8 | 116 | 47.61 | 1681 | 47.21 | 1667 | 280 | 375 | 92 | 3400 | 2400 | 2200 | 5100 | DN100 | ||

| 10 | 145 | 43.58 | 1539 | 41.23 | 1456 | 280 | 375 | 92 | 3400 | 2400 | 2200 | 5100 | DN100 | ||

| DWW-315W | 7 | 102 | 52.44 | 1852 | 52.30 | 1847 | 315 | 425 | 92 | 3400 | 2400 | 2200 | 5150 | DN100 | |

| 8 | 116 | 52.40 | 1850 | 52.27 | 1846 | 315 | 425 | 92 | 3400 | 2400 | 2200 | 5150 | DN100 | ||

| 10 | 145 | 47.53 | 1678 | 46.60 | 1645 | 315 | 425 | 92 | 3400 | 2400 | 2200 | 5150 | DN100 | ||

| DWW-355W | 7 | 102 | 70.38 | 2485 | 71.97 | 2541 | 355 | 475 | 92 | 3800 | 2350 | 2400 | 6800 | DN125 | |

| 8 | 116 | 69.56 | 2456 | 59.60 | 2104 | 355 | 475 | 92 | 3800 | 2350 | 2400 | 6800 | DN125 | ||

| 10 | 145 | 58.66 | 2071 | 58.65 | 2070 | 355 | 475 | 92 | 3800 | 2350 | 2400 | 6800 | DN125 | ||

| DWW-400W | 7 | 102 | 80.75 | 2851 | 77.36 | 2731 | 400 | 535 | 92 | 3800 | 2350 | 2400 | 7200 | DN125 | |

| 8 | 116 | 71.55 | 2526 | 71.75 | 2533 | 400 | 535 | 92 | 3800 | 2350 | 2400 | 7200 | DN125 | ||

| 10 | 145 | 69.43 | 2451 | 62.87 | 2219 | 400 | 535 | 92 | 3800 | 2350 | 2400 | 7200 | DN125 | ||

*) FAD in accordance with ISO 1217 : 2009, Annex C: Absolute intake pressure 1 bar (a), cooling and air intake temperature 20 °C

**) Noise level as per ISO 2151 and the basic standard ISO 9614-2, operation at maximum operating pressure and maximum speed; tolerance: ± 3 dB(A)

***) N/A-Not Available

****) W-Water cooling

Low Pressure Oil-free Screw Air Compressor Technical Parameters:

|

Model |

Maximum working pressure |

Capacity(FAD)* |

Installed motor power |

Cooling |

Noise Level** |

Dimensions (mm) |

Weight |

Air Outlet Pipe Diameter |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

50 Hz |

60 Hz |

||||||||||||||

|

bar(e) |

psig |

m³/min |

cfm |

m³/min |

cfm |

kW |

hp |

dB(A) |

L |

W |

H |

kG |

|||

|

DWL-55-2 |

2.5 |

37 |

15.33 |

541 |

14.44 |

510 |

55 |

75 |

Air Cooling |

69 |

2400 |

1800 |

1700 |

2500 |

DN80 |

|

DWL-55-3 |

3.5 |

51 |

12.78 |

451 |

10.85 |

383 |

55 |

75 |

69 |

2400 |

1800 |

1700 |

2500 |

DN80 |

|

|

DWL-75-2 |

2.5 |

37 |

19.92 |

703 |

20.35 |

719 |

75 |

100 |

69 |

2400 |

1800 |

1700 |

2650 |

DN80 |

|

|

DWL-75-3 |

3.5 |

51 |

16.30 |

575 |

15.87 |

560 |

75 |

100 |

69 |

2400 |

1800 |

1700 |

2650 |

DN80 |

|

|

DWL-90-2 |

2.5 |

37 |

26.07 |

921 |

26.45 |

934 |

90 |

120 |

72 |

2400 |

1800 |

1700 |

2750 |

DN80 |

|

|

DWL-90-3 |

3.5 |

51 |

19.54 |

690 |

19.49 |

688 |

90 |

120 |

72 |

2400 |

1800 |

1700 |

2750 |

DN80 |

|

|

DWL-110(W)-2 |

2.5 |

37 |

33.16 |

1171 |

29.90 |

1056 |

110 |

150 |

72 |

3000 |

2000 |

2000 |

3500 |

DN125 |

|

|

DWL-110(W)-3 |

3.5 |

51 |

25.60 |

904 |

23.92 |

845 |

110 |

150 |

72 |

2400 |

1800 |

1700 |

3000 |

DN80 |

|

|

DWL-132(W)-2 |

2.5 |

37 |

40.24 |

1421 |

40.98 |

1447 |

132 |

175 |

72 |

3000 |

2000 |

2000 |

3600 |

DN125 |

|

|

DWL-132(W)-3 |

3.5 |

51 |

27.23 |

961 |

29.43 |

1039 |

132 |

175 |

72 |

2400 |

1800 |

1700 |

3100 |

DN80 |

|

|

DWL-160(W)-2 |

2.5 |

37 |

49.42 |

1745 |

49.21 |

1738 |

160 |

215 |

76 |

3000 |

2000 |

2000 |

3900 |

DN125 |

|

|

DWL-160(W)-3 |

3.5 |

51 |

35.75 |

1262 |

34.98 |

1235 |

160 |

215 |

76 |

3000 |

2000 |

2000 |

3800 |

DN125 |

|

|

DWL-185(W)-2 |

2.5 |

37 |

56.02 |

1989 |

57.17 |

2019 |

185 |

250 |

79 |

3000 |

2000 |

2000 |

4100 |

DN125 |

|

|

DWL-185(W)-3 |

3.5 |

51 |

42.21 |

1490 |

44.16 |

1559 |

185 |

250 |

79 |

3000 |

2000 |

2000 |

4000 |

DN125 |

|

*) FAD in accordance with ISO 1217:2009, Annex C: Ansolute intake pressure 1 bar (a), cooling and air intake temperature 20℃

**) Nosie level as per ISO 2151 and the basic standard ISO 9614-2, operation at maximum operating pressure and maximum speed; tolerance:±3 dB(A)

Specifications are subject to change without prior notice

|

Rotary Screw Air Compressor |

PM VSD Double Stage Air Compressor |

|

Diesel Portable Screw Air Compressor |

Oil free Air Compressor |

|

Compressed Air Treatment Equipment |

hi